A few years ago, almost everyone had met the "screen entry", but why did we stop discussing the problem these years? Because at present, even thousands of Yuan entry machine also adopts the way of screen GFF full fit, but do you know the difference between GFF, OGS, TOL, on-cell and in-cell in the full screen?

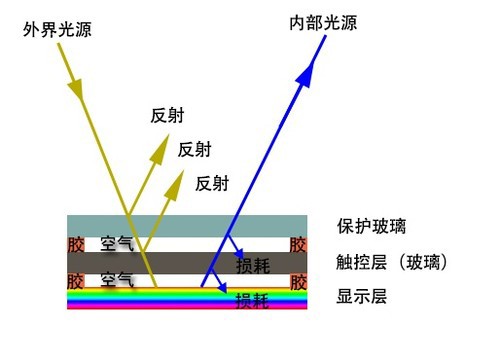

In the past, the biggest problem of screen is the poor permeability. When it's screen, it can see that the screen is a large gray rectangle, which is mainly related to its structure. Most of the screen can be simplified to three layers: "glass + touch layer (glass) + display layer".

The ordinary screen structure doesn't look transparent

For ordinary screen, will be more than three layers are fixed together on the need to use the adhesive, the early process is just to stick around and inter layer, so inevitably occur in the middle of the air layer, the three layer structure of two layers of glass + two layers of air will lead to light reflection, thus leading to the very a bad impression, even outdoor is very easy to see the screen.

GFF solves the problem of ray reflection between multilayer structures

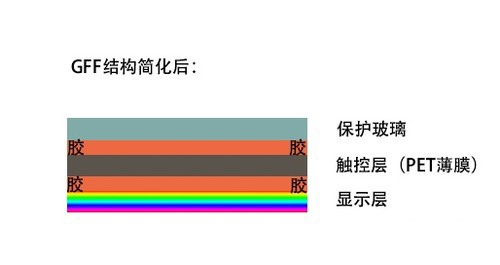

In order to solve the problem that the screen is not transparent and the size is thicker, the GFF process appears. It directly to the above non laminating intermediate layer of glass for touch PET films, and optical glue (glue) completely filled air layer, and less of a layer of glass and the air layer is filled with water gel, reflection phenomenon significantly reduced, resulting in a very significant upgrade perception of the screen is no longer is grey.

At present, some models are GFF full fit as a propaganda point

Because the touch layer of GFF technology is still independent, so the "GFF full screen" is not exactly right, or it's more like a whole fit and incomplete fit. GFF has been popularized in most of the medium and low end models at present. It has the characteristics of low technological difficulty, high rate of good products, and the difference between the impressions and the full fitting process is not very large. So many manufacturers' middle and low end models use the GFF screen. In addition, the GFF process is tightly combined with the multi-layer structure, so the screen panel is usually changed after the screen is broken.

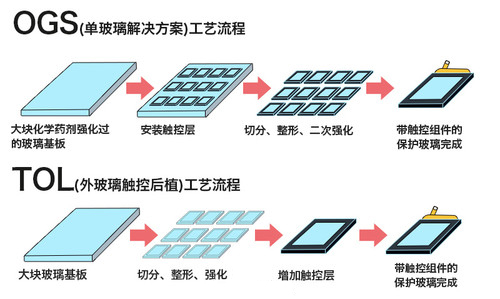

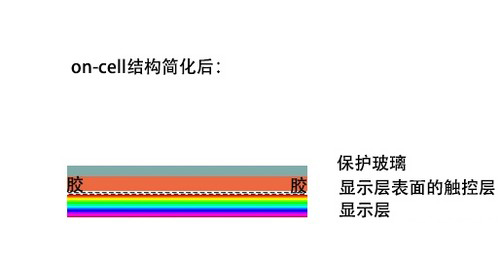

n fact, it's the whole fitting screen from here. The OGS full fit means that the touch layer is directly inside the protective glass, so the whole screen is changed from three layers of glass + touch layer + display layer to two layers of "glass (with touch) + display layer", and the thickness is reduced. The two layers are still combined with water glue, and the permeability is a boost compared to the above GFF. At the same time, as the touch layer is next to the screen protection glass, OGS also brings the improvement of touch sensitivity. There are many high-end Nubia models such as Nubia Z9 mini and so on in the domestic models.

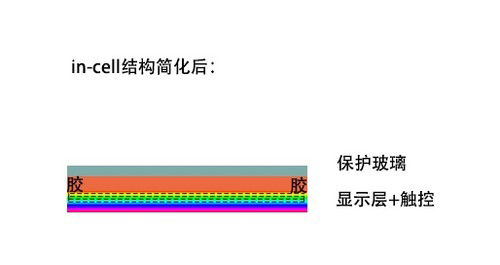

Summary: at present the fitting process of the screen in perceptions are very good, and the gap between them is compared also difficult to detect, so apple is not using in-cell means it's perception of the best, in fact it is the advantages of in-cell ultimate slim. OGS is highly sensitive to touch to a certain extent, but the disadvantage of OGS is that cutting in the manufacturing process will affect the strength of the glass panel and make it fragile. In addition, many manufacturers will be in the thousand machines will be "GFF full fit" as a propaganda point, but you also have seen above all fit the GFF is not in the strict sense, but we can't go to black, after all, in the low-end equipment especially the main cost of the thousand machines at the beginning of the design, the cost of consideration is more stringent than the flagship machine.